ADVERSE CONDITIONS, Reliable PERFORMANCE.

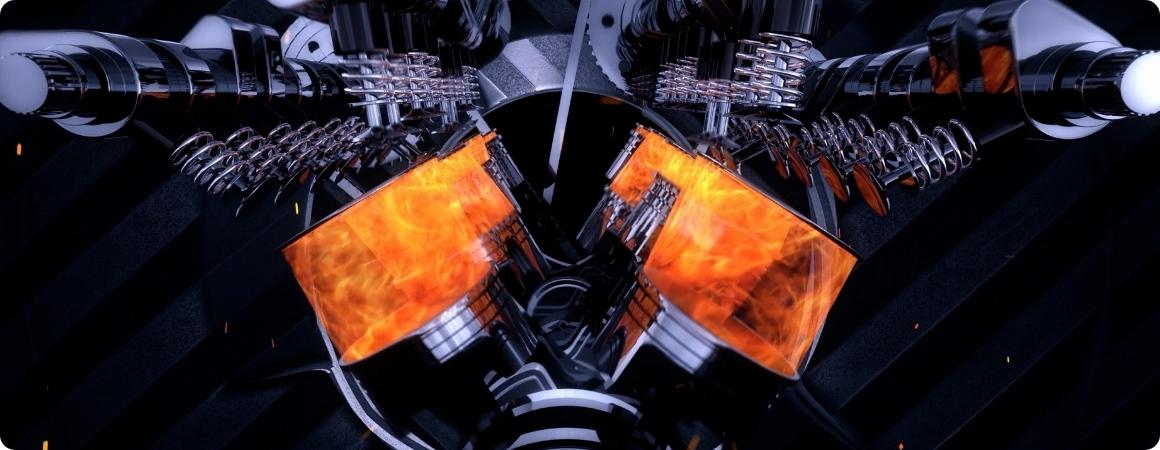

Automotive manufacturers are consistently reducing the size of the power trains and engines to reduce fuel consumption. Unfortunately, this results in increased temperatures and material stress within confined areas.

Elevated temperatures and corrosive fumes and fluids rapidly degrade ordinary elastomer materials. Hence the need for made-to-purpose rubber compound materials that adhere to customer specifications.